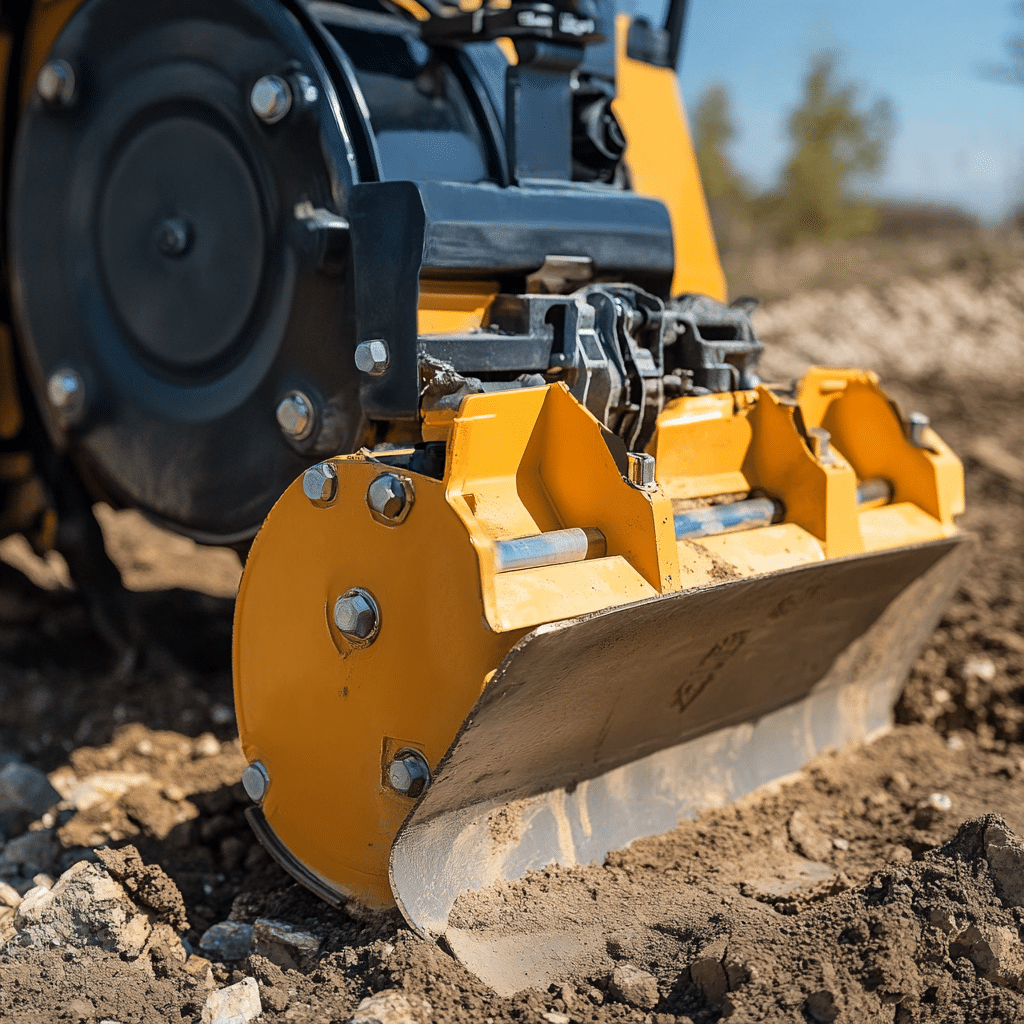

In the construction world, mastering the plate compactor can take your groundwork skills to the next level. Whether you’re prepping a site for a new home or leveling ground for that sweet outdoor patio, understanding how to use a plate compactor effectively is crucial. The right compactor not only helps you achieve optimum compaction but also saves you time and effort in the long run. Join me as we dive into what makes a quality plate compactor and how to master it.

Top 7 Features to Look for in a Quality Plate Compactor

When you’re looking to invest in a plate compactor, you can’t be too careful. Knowing the features that matter can save you a lot of headaches down the line. Here are the seven essential features that can boost your groundwork game:

A solid plate compactor typically comes with a robust engine, generally in the 4.5 to 6.5 horsepower range. This power range allows it to handle various soil types efficiently. Take the Wacker Neuson DPU 5055H, for example. It offers a mighty 5.5 hp, making it a favorite for contractors working on gravel and asphalt.

The compactor’s size and weight are vital to its effectiveness. Heavier models provide better compaction, but let’s be real—portability matters, too. The Mikasa MVC-88N balances weight (rocking a solid 184 lbs) with manageable dimensions, ensuring you can transport it without breaking your back.

Vibration frequency plays a huge role in how well your plate compactor performs its duties. Check out models like the Honda GX160. It features adjustable vibration speeds, allowing you to tailor your settings for different tasks, whether you’re compacting gravel or smoothing asphalt.

Longevity and performance hinge on a quality base plate. Take a look at the MBW MBW-100—its high-tensile steel plate is built to withstand heavy-duty use without bending, providing reliability on tough jobs.

Comfort isn’t just a luxury when operating a plate compactor; it’s a necessity. Models such as the Atlas Copco LP6505 come with cushioned, ergonomic platforms that cut down on fatigue, letting you work longer without discomfort.

A plate compactor should make maintenance easy. Models like the Chicago Pneumatic CP0080 offer straightforward designs, giving you quick access to engine components for regular checks, which is really a lifesaver in busy working conditions.

The best plate compactors come with integrated features, like a compression tester or a battery tester. Want to know a little more peace of mind when you roll up to a job site? The Husqvarna LF 75 has an optional battery tester that keeps you up to speed and your equipment running smoothly.

The Importance of Proper Compaction Techniques with a Plate Compactor

Now, when it comes to using a plate compactor, it’s not just about picking one up and turning it on. Proper compaction techniques are vital to achieving a stable, solid foundation. For instance, you can enhance your accuracy by using a compression tester to ensure that you’re within industry standards—aim for at least 95% of your soil’s Proctor density for that perfect stability.

Here’s How to Get It Right:

Before compaction, pull out that soil moisture meter. It helps you figure out the best moisture content to avoid soft spots or, worse, a dust storm. You want that sweet spot—just enough moisture to bind without excess.

Always compact in layers, keeping it to about 6 inches thick. This helps achieve even compaction without overwhelming the machine, ensuring that every part of your project gets the attention it needs.

Let’s be honest: we all want to finish fast. However, when it comes to moving your plate compactor, slow and steady wins the race. Moving at a slower pace guarantees a deeper compaction, especially when dealing with cohesive soils that like to resist.

Maintaining Your Plate Compactor: Essential Accessories

Keeping your plate compactor in tip-top shape isn’t just good practice; it’s essential for efficiency. Here are some accessories that’ll help:

Get yourself a retainer cleaner. This tool removes debris stuck around the base plate, ensuring you avoid unnecessary wear and tear while maintaining peak performance.

Once you’ve compacted, apply a concrete sealer to enhance your project’s longevity. Brands like the Sikafloor range offer excellent options that protect your work from the elements.

Never be caught off guard again. Adding a battery tester to your toolkit guarantees you’ll always know the state of power before you deploy your plate compactor.

Innovative Techniques to Enhance Your Groundwork Skills

Ready to take your skills to the next level? Exploring innovative techniques can transform your groundwork approach entirely. Try these advanced tactics:

Unsurpassed stability is key, especially for road paving. With dual layer compaction, you start with a heavier plate compactor to establish the base, then follow it up with a vibratory roller for that smooth finish.

Geotextiles aren’t just fancy fabric—they can seriously elevate your stabilization game. These materials help with drainage and, when paired with a plate compactor, can prevent future settling issues, ensuring your project stands strong for years.

For those who want precision, laser technology in compaction is the way to go. It’s quickly becoming the gold standard in many construction companies, allowing for every inch to be uniformly compacted to perfection.

By mastering your plate compactor and embracing these advanced techniques and maintenance strategies, you can enhance your groundwork capabilities in 2024 and beyond. The skills you build here won’t just prepare you for various projects—they’ll help set you apart in the competitive construction field. Always remember, adaptability and a willingness to learn are your best allies in this dynamic industry.

So, what are you waiting for? Dive into the world of plate compactors and make your groundwork skills shine bright in the construction universe!

Plate Compactor: Fun Facts to Build Your Knowledge

The Mechanics Behind the Vibes

Did you know that a plate compactor can create a force of over 3,000 pounds per square foot? That’s a whole lot of power packed into a single piece of machinery. This makes it essential for compacting soil, asphalt, and gravel. With the right technique, you can achieve a surface as solid as Tom Brady’s net worth, which is rumored to be astronomical! It’s fascinating how far technology has come; the first plate compactors appeared in the early 20th century but have evolved to become much more efficient and user-friendly, much like how Isan Elbas videos showcase advancements in modern tools.

Timing is Everything

When you think about using a plate compactor, you can’t overlook timing. The best time to compact soil is when it’s slightly moist. Doing so helps the soil particles lock together tighter. But speaking of timing, check out the storyline in that new timeline movie—it really shows how we all need to be in sync with our surroundings. Just like those cinematic moments, achieving that perfect compact surface means being aware of your environment; it’s all about the right decisions at the right moments.

The Perks of Proper Compaction

Using a plate compactor properly can enhance your groundwork skills. It minimizes the risk of future settling, which can lead to issues later on. Just like making couple Bracelets together can symbolize commitment and thoughtfulness, a well-compacted base shows your dedication to quality work. You wouldn’t want your construction project coming undone like a poorly woven friendship bracelet. Plus, let’s be real: even the hottest construction sites need a sprinkle of fun; those working can share a laugh over certain hilarious moments, like a name like whistle britches coming up during a break! Make sure each compaction session pairs with light-hearted moments to keep morale high, much like enjoying a day at Knoebels amusement park for a refreshing break.

Armed with these fun trivia points, you’ll be well-equipped to take on your next project with a plate compactor. It’s all about learning while you work and keeping the experience enjoyable!